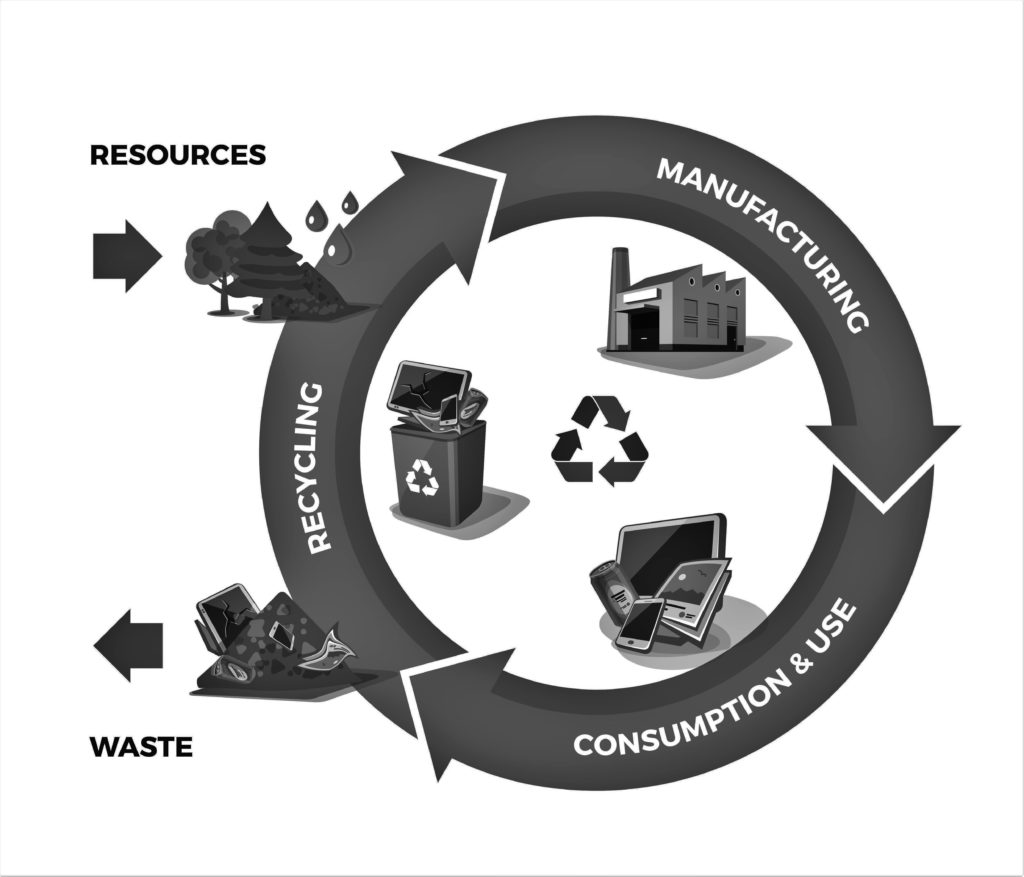

Every product has a life cycle and understanding the components of the lifecycle is important for getting to grips with its true environmental impact. Traditionally, environmental impact assessments have considered just the manufacturing phase of a product – this would include direct impacts. Direct impacts are those that are physically released by the organisation itself. For example emissions from a boiler on site that causes air pollution or the discharge of oil into a nearby river causing damage to the river. They generally include pollution issues. These can be significant for some organisations and obviously need to be carefully assessed and controlled.

Upstream Impacts

However, considering direct impacts does not give a very accurate picture of the environmental impact of an organisation and the products that it manufactures. Think of it this way, an organisation may manufacture a product but this phase of the lifecycle may have a relatively low impact on the environment. However, the extraction of the materials from the environment, their processing and distribution to the manufacturer could have a significant impact. Such activities will vary depending on product but might include activities such as mining, agriculture or transport of the product to the production facility etc. Some or all of these may have a much bigger environmental impact than what occurs at the production facility. Such environmental impacts are not directly created by the organisation so are often known as ‘indirect’ impacts. We may also use the term ‘upstream’ impact, as they originate from above the manufacturing part of a products lifecycle.

You might be wondering why such impacts would be relevant to an organisation – the answer is that the organisation is still ‘driving’ them as it buys and uses the raw materials to make a product. The organisation does, therefore, contribute to the products overall environmental impact.

Downstream Impacts

We also need to consider the impacts that occur ‘downstream’ of the manufacturing process. Such impacts would include those that occur when a product exits the manufacturing facility. This might include the impacts associated with the sale, distribution, use, and disposal of the product. Just like the ‘upstream’ impacts these can in some cases be significant. Imagine that you purchase a car; it might be shipped from a country on the other side of the world, driven for around 10 years and then scrapped. With this example it is clear that there are much greater environmental impacts associated with these activities than with the manufacture of the car.

Why Bother?

The consideration of the full lifecycle and the environmental impacts associated with it is key if an organisation wants to fully reduce its impact on the environment. Many actions could be taken by an organisation to reduce the impact of its ‘direct’ operations, for instance making production facilities more energy efficient or reducing waste from product lines.

An organisation can also do a great deal on both the ‘upstream’ and ‘downstream’ aspects of the lifecycle. On the upstream side it may set specifications for the growth, extraction or manufacture of the materials or products that form parts of the product it manufactures such that they originate from more sustainable sources. On the downstream side there could be interventions that reduce the impact of the product while in use. Examples of this approach include; designing a product so that it uses less electricity, or fuel so making a car lighter or optimising the firmware of a Smartphone such that it uses less power and does not need to be charged as often as the previous generation of Smartphone. The disposal phase could also be considered by an organisation, interventions to reduce impact might include reducing the amount of packaging on a product or reducing the amount of material used to make the product, both cutting down on the amount of waste when it comes to the end of its life. Specifying the product to be made from easily recycled materials or eliminating hazardous substances from a product or its packaging would also likely reduce the environmental impact of the disposal of the product.

It is clear therefore that to get an accurate idea of environmental impacts that the full lifecycle of a product should be considered, both upstream and downstream, rather than considering just the impacts of the manufacturing phase.

–

John Binns BSc (Hons), MSc, MSc, MISEP (formerly IEMA)

With over 19 years’ experience working in environment management, John Binns BSc (Hons) MSc MISEP (formerly IEMA) is an experienced environmental tutor and consultant with knowledge of health and safety management.